The cowl baffle is designed to force all the cooling air, that enters through the openings of the cowl inlet, over the tops of the cylinders, and then down through the bottom back part of the cowl. This hopefully gives the most efficient cooling flow of air over the engine. The idea is that the top, underside part of the cowl forms a seal with the parts installed in this section.

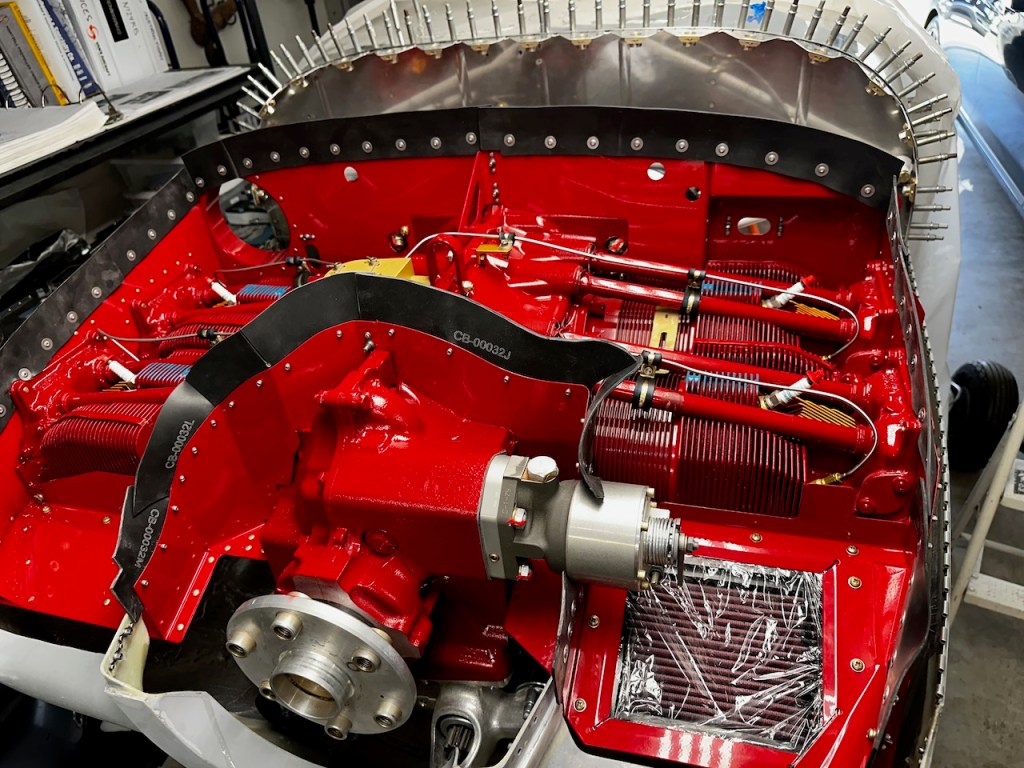

I previously sent all the baffle parts to a powder coater and had them coated fire engine red. I wanted to match the red of the engine. While not exact, it is close, and the baffle makes the engine pop red at you. Too bad it will be hidden by the cowl most of the time.

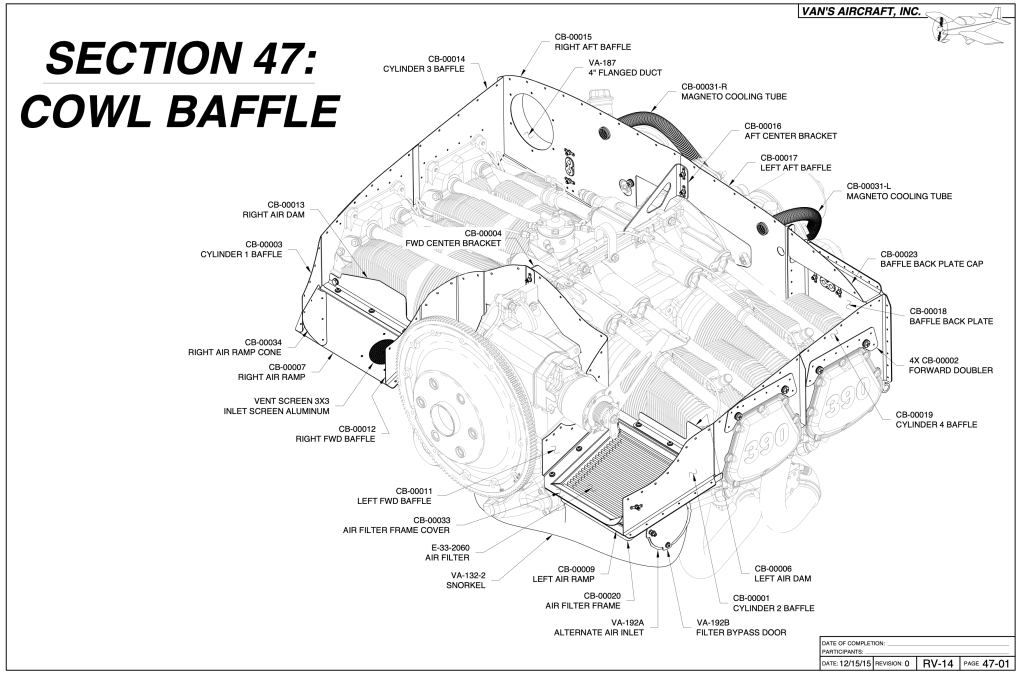

The following shows the various parts riveted together and attached to the engine. If my memory serves, there were about 31 pieces.

A rubberized gasket material is riveted to the top of the aluminum pieces giving more of a seal keeping the air flow moving through the cylinder fins.

The final step consisted of sealing off all the gaps between the aluminum parts and the engine.