This was the big step: receiving and installing the engine. I ordered a Lycoming IO-340EXP119 Thunderbolt engine from Vans in Dec 2021. The original delivery date was sometime in October 2022 but I never expected, or wanted it, until later. It finally was delivered in early July which turned out to be perfect timing because I was ready to install it immediately.

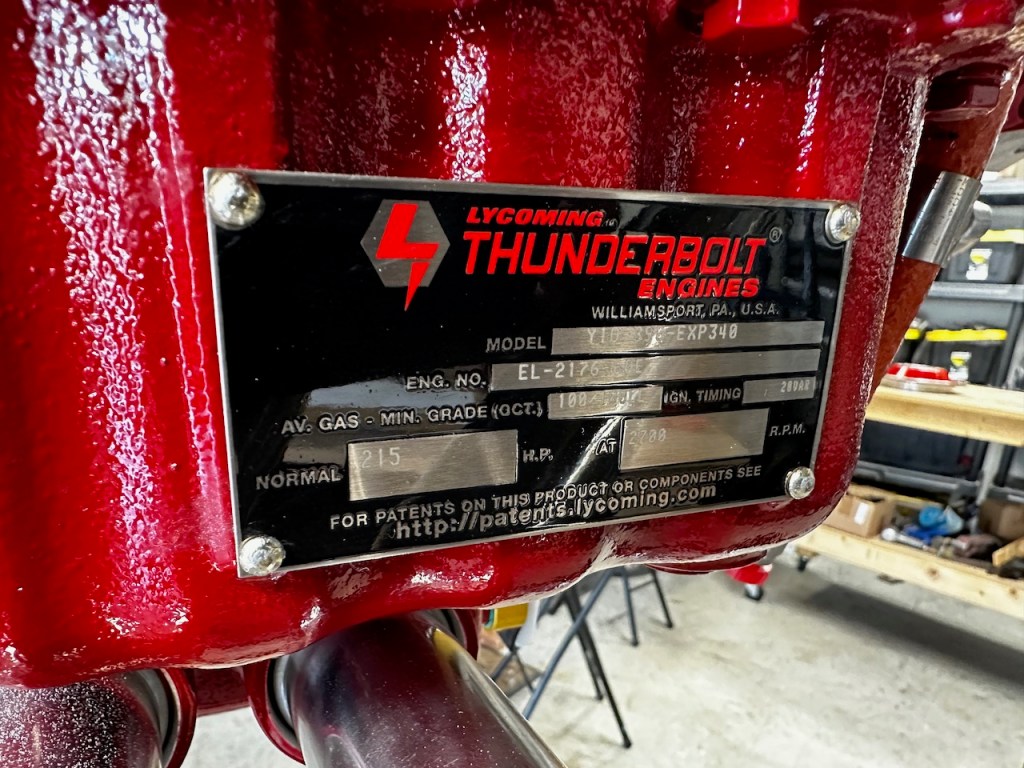

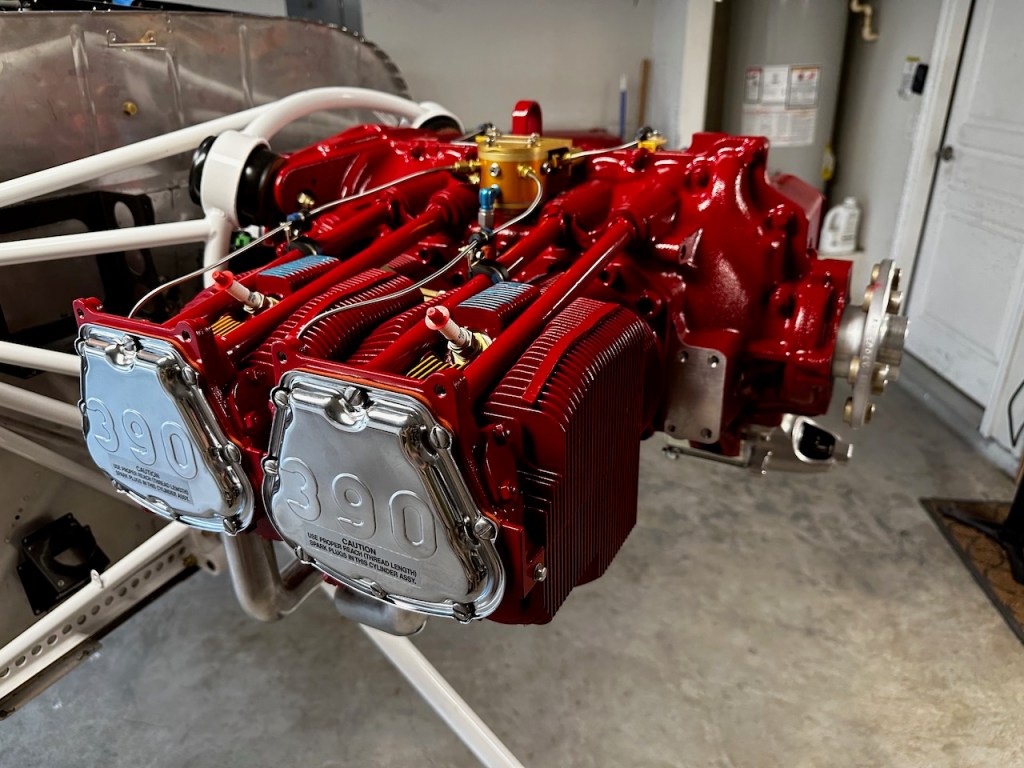

Because everyone asks, this is an aircraft specific, 4-cylinder, horizontally opposed, piston, direct drive, angle valve, fuel injected, 390 cu in, 215 HP (at 2700 rpm), 308 lbs engine built by Lycoming (a division of Textron who owns Cessna, Beechcraft) located in Williamsport, PA. I think I answered all the normal questions. Oh yeah, the EXP is a slightly upgraded version of the IO-390 with slightly more horsepower due to a newly design cold air induction along with an Airflow Performance fuel injection system. The Thunderbolt part means the engine was hand-built by a small team of Lycoming technicians doing things like balancing the rotating system within tight tolerances, and polishing the inside of the cylinders resulting in hopefully smoother operation. Thunderbolts are also painted with a variety of colors (I chose red), they and come with Chrome rocker covers. And yes, a bit extra cost and longer lead times.

So, on July 1, a cardboard box arrived which contained inside something about the same value as an average new car.

I couldn’t wait to get home for the unboxing

The engine was surrounded by the spray foam stuff which wasn’t that easy to remove.

After about an hour of breaking away foam, Big Red made its appearance in a plastic bag with desiccant.

Removing the bag, it sure looked pretty.

The big toothy thing is the flywheel which engages the starter.

Hanging the engine is not all that difficult or time consuming but I had an expert (my EAA tech counselor) and a curious fellow pilot come by to offer their assistance. I might have been able to do it myself but the task was much smoother and more fun with the help.

The biggest trick was to line up the engine mount points to the 4 engine mounts. Some up and down with the engine hoist and shaking back and forth eventually accomplished the task.

A 5/8″ wrench was sacrificed to the tool gods by grinding down and thinning it out a bit in order to reach some engine mount bolt heads.

Big Red was looking great but now that it is on the airplane, it looks surprisingly compact.

Many years ago I saw a blog where a bunch of old guys had an engine hanging party in a garage, and I always admired the look of satisfaction of the guy who was building his airplane in the garage. Well, this is the look of satisfied of a couple of old guys building an airplane in the garage.

A few photos of some engine components. First, the alternator:

B&C upright oil filter (Aftermarket mod):

E-Mag Pmags – two of them. Replacements for the old traditional magnetos.

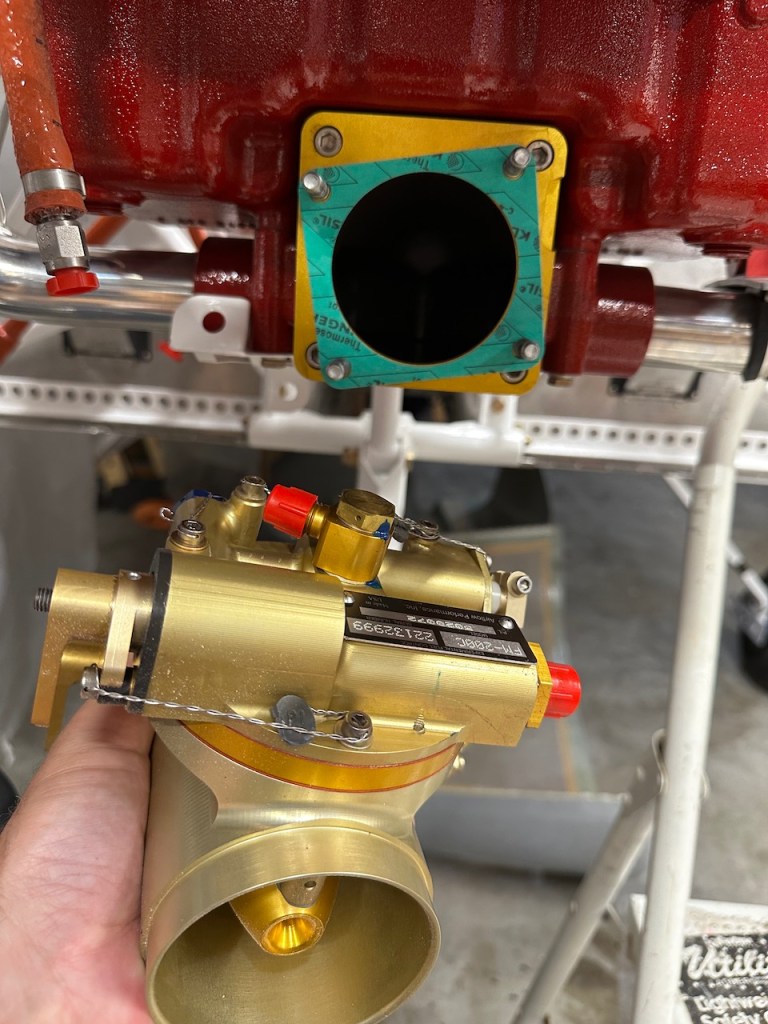

Airflow Performance Fuel Injection system:

Usually a 300 cu in engine was considered a fairly big 6 cylinder block for a p/u truck and you have a 390 ci 4 cylinder engine. Amazing. You do look very satisfied. I would not have had the courage you do, so hat’s off to you.

Aircraft engines are big displacement/low rpm (2700rpm) due to prop. The prop is limited in that you don’t want the tips to exceed the speed of sound.

Congratulations! I installed mine in May and it is a very rewarding piece of work