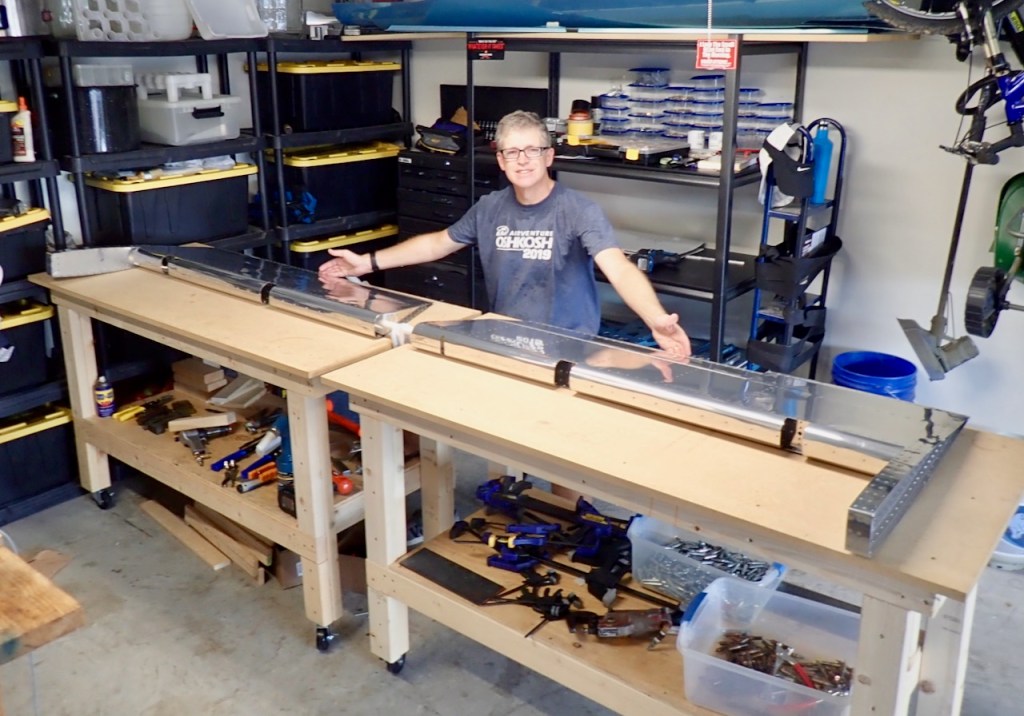

Wow, finally done. I never expected this to take so many hours, and I look back, and I am not sure why it took so long. 67 out of 172 hours total so far was spent on both elevators. Not sure what I am looking at timewise with the Aft Fuselage. Perhaps just as much time as I have spent so far?

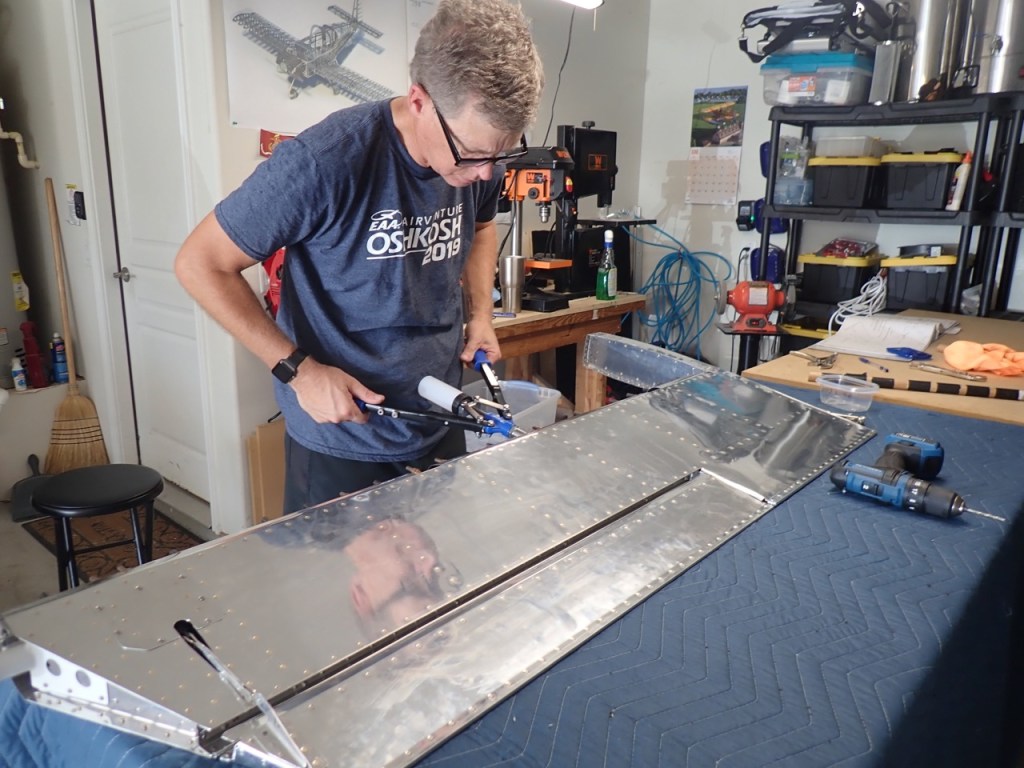

We previously left off with the riveting of the skins to the spars. I didn’t get any pictures of this but the next step involved buttering the foam block ribs, and inserting them into just before the trailing edge. The substance used was “Proseal”, and I now know why people call it “Black Death”. It was the gooiest, stickiest material I have ever encountered. I am amazed it didn’t get all over the metal parts, my clothing, and me.

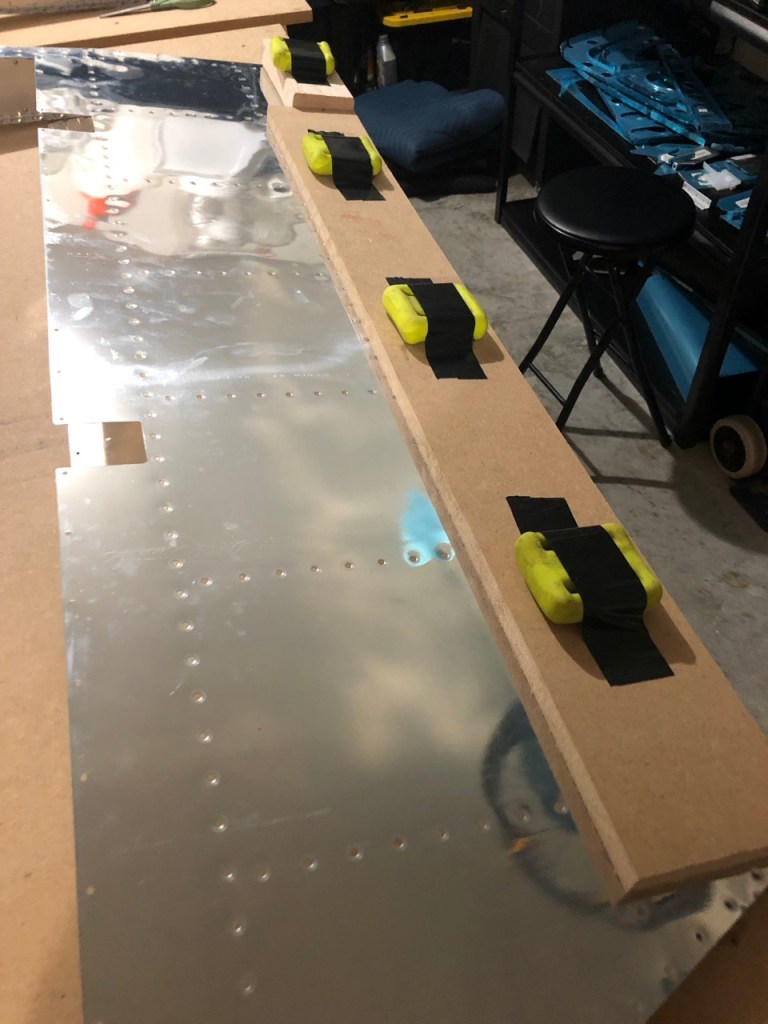

After inserting the ribs, it was time to insert the trailing edge wedge using the same double sided 3M tape that was used on the rudder. Then, all the dimpled holes were cleco’d and a weighted board was placed over the areas of the ribs. My collection of scuba weights came in handy – with a little duck tape of course.

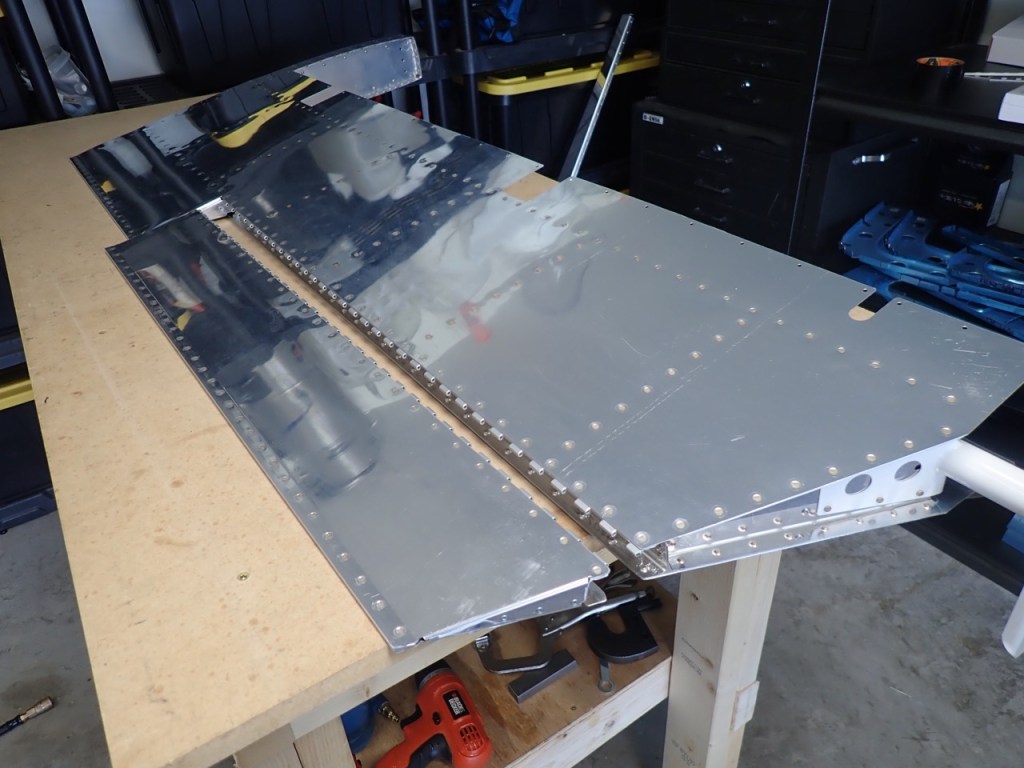

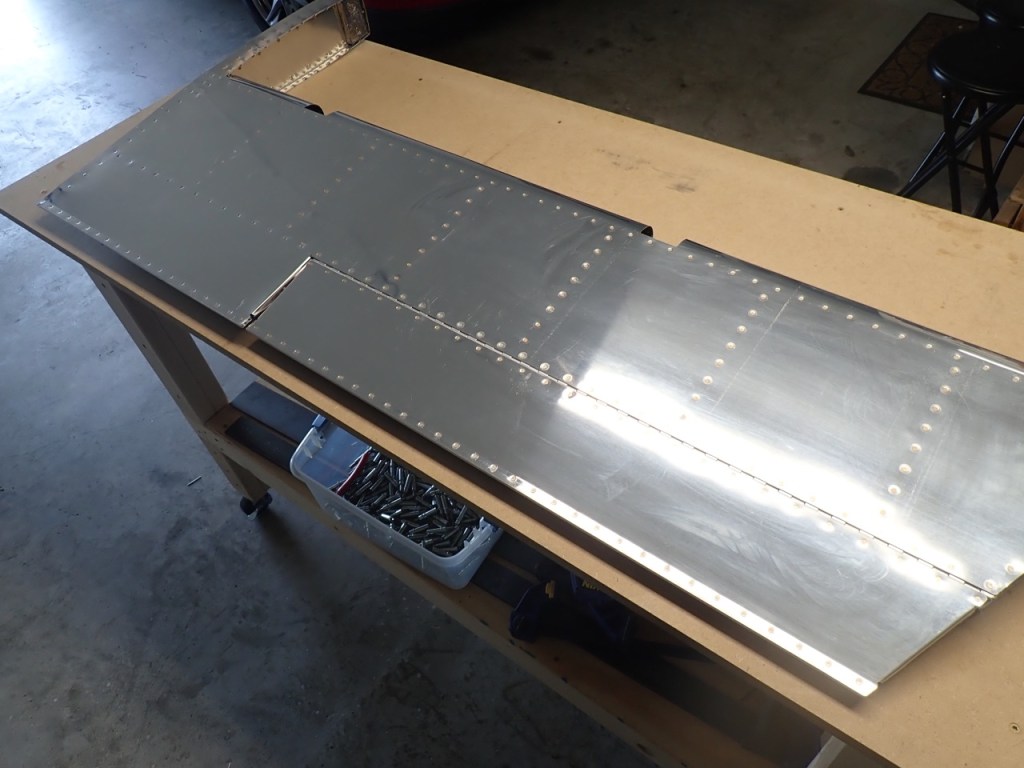

The trailing edge was double flushed riveted using a special squeezer set by Cleveland Tool. This squeezer set was ground to the correct angles of the trailing edge so I was able to use the squeezer instead of the hybrid back riveting method used on the rudder.

The trim tab was finished off the same way as the trailing edges of the elevator. Some MK-329-BS blind rivets were used on the close-out tabs on the side of the trim tab.

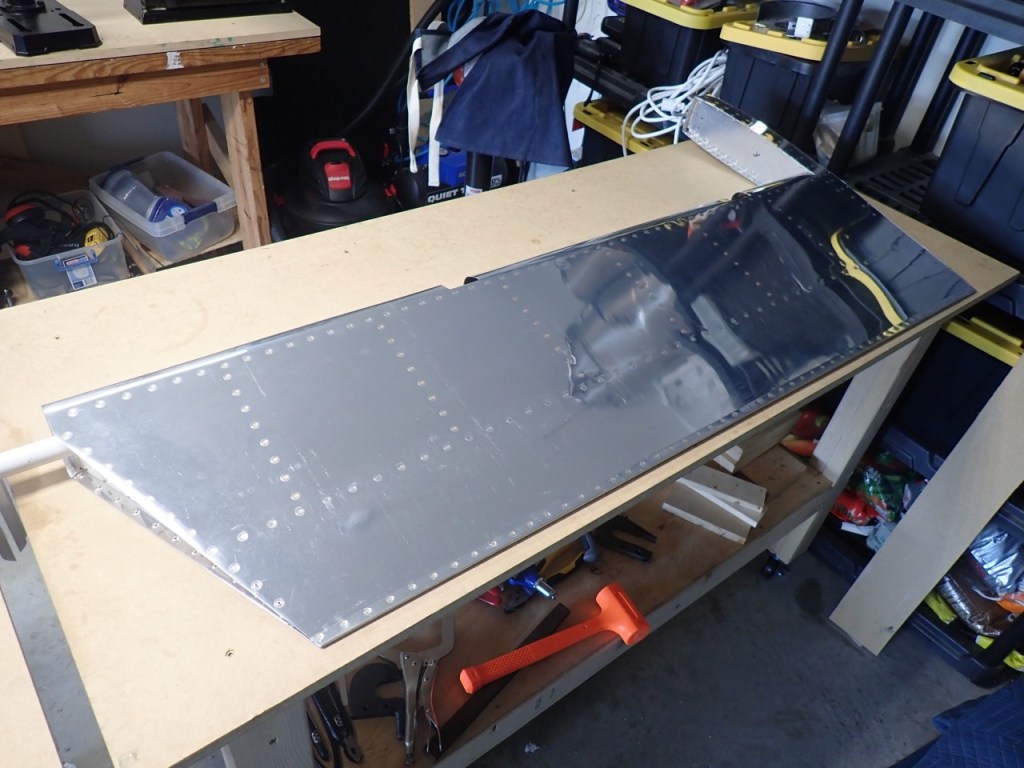

The hinges of the trim tab and the left elevator were then mated together, the piano wire was inserted (after bending it a certain way), and my first safety wiring attempt was done to ensure the piano wire doesn’t back itself out.

The trim tab seemed to sit nicely in its slot in the left elevator.

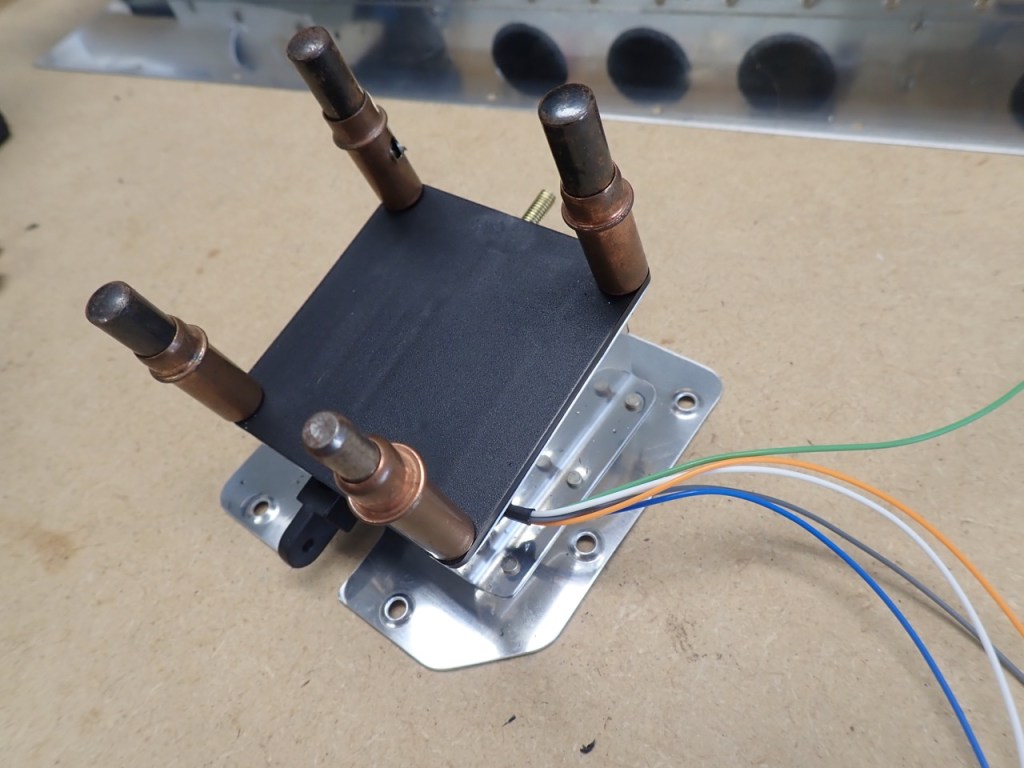

The trim tab servo was mounted on brackets and inserted into the rectangular hole on the bottom of the left elevator.

A source of huge anguish, sweating, and swearing with the rudder, I then attacked the leading edges. Having a better attitude certainly helps because I felt this was an easy process this time.

For some reason, the collection of AD-41-ABS Blind Rivets came up short one rivet. I will be placing an order for more with Vans tonight.

Each elevator then got a lead counterbalance weight.

I think the elevators came out very nicely in the end.

Looks like a bunch of tail feathers are finding their way into the house.