I think these last few sections of the HS illustrated to me the amount of work this airplane will take to complete. While being only a few pages in the plans, there were a lot of individual steps to complete in order for me to come out of the garage with a completed horizontal stabilizer.

After leaving the previous sections, work commenced on the HS skins. First, they had to be deburred, and then the stressful act of dimpling. I say stressful because my previous two attempts at skin dimpling resulted in a double dimple. I concentrated on each hole, and was successful in not doing it here.

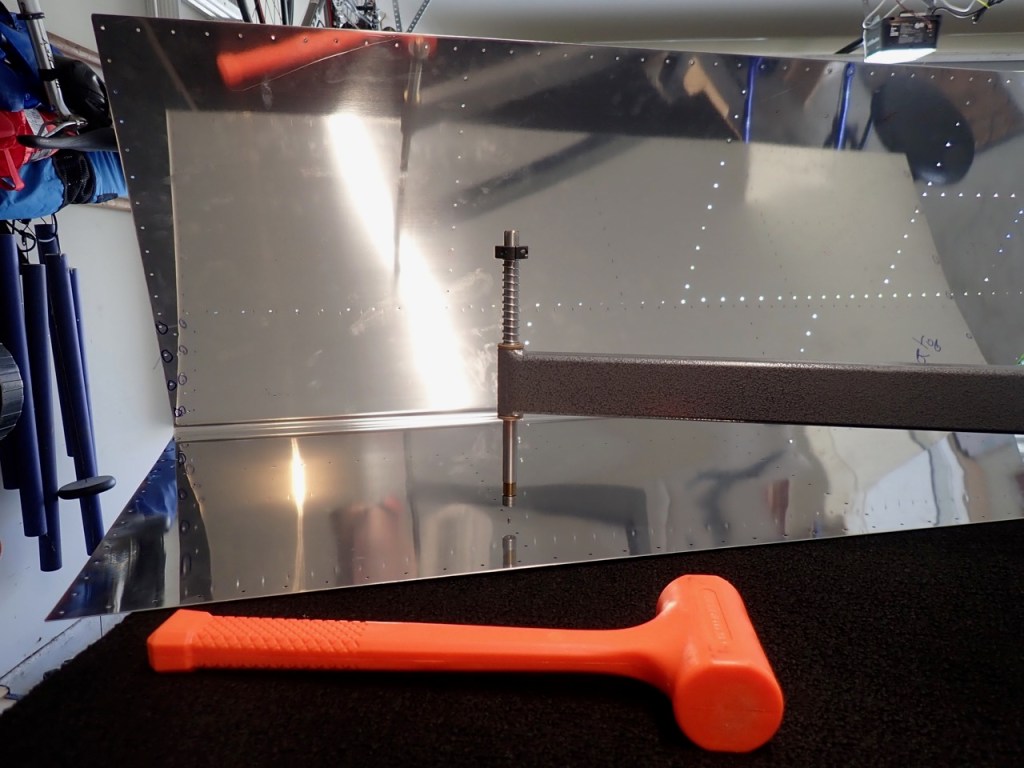

Each hole was placed in the C-Frame, and the dead blow hammer was used to imprint the dimple in the skin.

The result was a nice dimpled skin.

The spars were then countersunk with the Microstop Countersink tool.

The dimpled skins were placed into the cradles made previously. Unfortunately the duct tape liner in the skins did not prevent the nice aluminum finish from getting wear marks. It doesn’t matter too much because the paint will easily cover this.

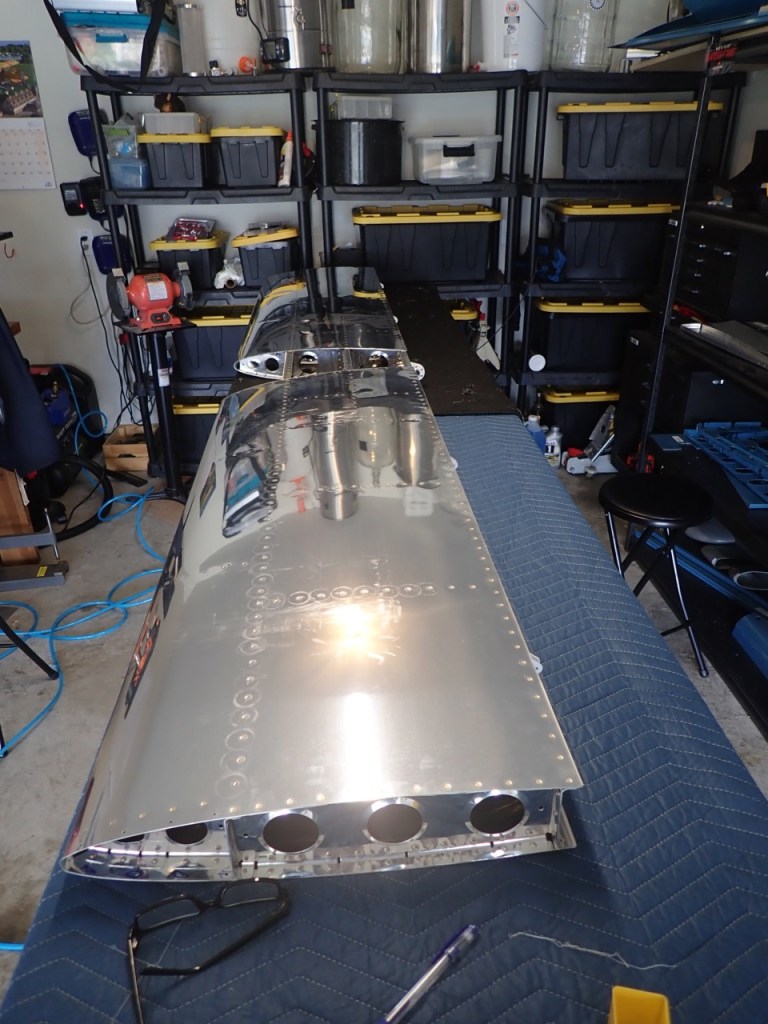

The front spar and ribs were cleco’d and riveted together which in turn was placed into the skins from the top. The precision of Van’s machining and punching of all the parts continued to amaze me. The HS is about 9.5 feet long, and every hole from one end to the other (48 holes) lined up exactly.

Then it was back to inserting nearly 300 cleo’s into the skin, rib and spar assembly.

I did not get any pictures of the rivet process. Most of the skin was riveted with a rivet gun and bucking bar. I basically had to reach down inside the skin with the bucking bar and hold the rivet gun against the skin. I was about 98% successful with the other 2% causing me to drill out the rivet and do it again. I think the end result was a bunch of good rivets.

Yesterday was the first time I had enough of the heat and humidity and decided to quit early in the day. Doing a last desperate move before I put money into a portable A/C, I decided to get one of these whirlwind fans to help circulate the air inside the garage better. So far, it seems to be working.

After all the bucking and rivet gun stuff was completed, the rear spar was inserted, and once again, all the holes lined up nicely.

Flying buddy, Chuck, and his grandson came over to help finish off the HS. We had a little assembly line action with a person inserting and/or removing cleco’s, another inserting rivets, and me using the pneumatic squeezer. In no time, we finished of 96 rivets.

I would like to congratulate Chuck’s grandson, Zach, for recently completed Basic Training for the Air Force. He is off to Yokota Air Force Base in a couple of weeks for his first duty station.

I like how the different parts are coming together that are starting to resemble an airplane.

On to the elevator….From the plans, this will have a very high level of complexity in the build.